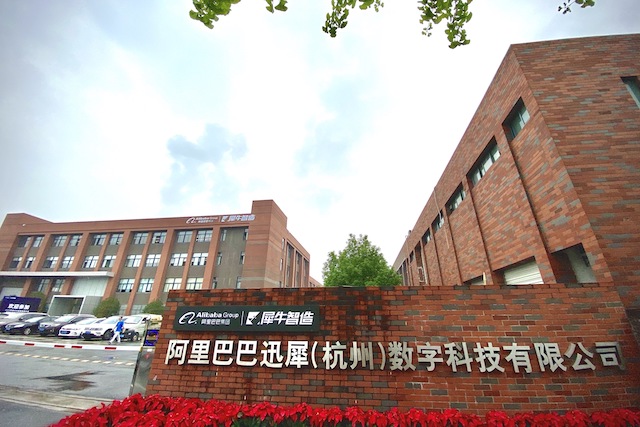

Alibaba Group revealed its New Manufacturing model for the first time with the unveiling of Xunxi Digital Factory (“Xunxi”) on 16 September 2020.

Powered by Alibaba’s cloud computing infrastructure and IoT, the Hangzhou-based factory offers SMEs a digitalized end-to-end manufacturing supply chain that allows for fully-customized, demand-driven production.

This gives smaller businesses and manufacturers in particular the ability to benefit from the digitalization of China’s over RMB30 trillion (over USD4 trillion) manufacturing market through being able to respond better and quicker to customers’ changing needs.

Data is the core of New Manufacturing and harnessing data insights is key to capturing new opportunities in the shift in consumer preference for personalized rather than mass-produced goods. New Manufacturing transforms traditional manufacturers with data-driven intelligence and technology to move towards a more agile model of production based on real-time demand,

said Alain Wu, CEO of Xunxi Digital Technology Company, Alibaba Group. “This allows traditional manufacturers to improve profitability and reduce inventory levels while still being able to meet these personalization needs.”

The introduction of New Manufacturing is another milestone in the implementation of Alibaba’s “Five New” strategy which was first introduced by founder Jack Ma in 2016 and comprises New Retail, New Manufacturing, New Finance, New Technology, and New Energy.

At an early stage, apparel was identified as the starting point for Xunxi – a sector in which the lengthy production cycles and high inventory levels have long been a problem for small and large players alike.

Powered by new technologies such as real-time resourcing, process and cost planning, automated in-house logistics and Xunxi’s manufacturing operating system, the factory is able to produce small-batch orders at reasonable costs and with shorter delivery times, consequently increasing manufacturing efficiency from 25% to an average of 55%.

Xunxi’s trend and sales forecast model alongside its own artificial intelligence-aided integrated product design platform give manufacturers insights into consumer preferences.

This enhanced information flow can reduce research and development costs and enable businesses to capture the fast-evolving opportunities for consumer personalization.

Apparel has consistently been one of the biggest categories on Alibaba’s retail marketplaces in China, which has given the company an unparalleled advantage in gathering customer insights.

In the past, excess inventory has led to a 30% loss in revenue across the industry. The Xunxi pilot demonstrates Alibaba’s commitment to making it easy to do business anywhere. Leveraging this ‘made-in-cloud’ production, SME businesses can stay competitive in the fast-moving fashion market.

Since its inception, the factory has collaborated with Taobao and Tmall merchants, live streaming broadcasters, and streetwear designers to explore and experiment with new possibilities of apparel manufacturing.

On September 14, the World Economic Forum (WEF) designated Xunxi Digital Factory a Lighthouse as part of its Global Lighthouse Network, a community of world-leading companies that have succeeded in adopting Fourth Industrial Revolution technologies at scale.

The designation recognizes Xunxi’s achievements in combining powerful digital technologies with consumer insight and bringing a fully digitalized New Manufacturing model to life.

The Xunxi showcase comes at a time when the COVID-19 pandemic is catalyzing an acceleration in the digital transformation of different industries.

In the future, Xunxi Digital Factory will help apparel customers reduce inventory levels even further while continuing to increase efficiency as well as the level of customization.

As the initiative progresses, the technology will be replicated into other sectors in addition to the current focus of fashion and apparel.